source:Industry News release time:2022-04-08 Article author:sznbone Popular:pcb

When the thermal requirements of the design are very high, using an aluminum-based PCB is a very effective solution. This design is able to better transfer thermal energy away from the design components, thereby controlling the temperature of the project. The efficiency of removing thermal energy from circuit components is typically ten times that of an equivalent fiberglass backsheet. This significantly higher level of heat dissipation allows for higher power and higher density designs.

Additionally, aluminum substrate PCBs are finding applications in high power/high heat dissipation applications. Originally specified for high power switching power supply applications, they have become very popular in LED applications. Examples of LED applications include traffic lights, general lighting, and automotive lighting. Adopting aluminum-based designs (LED PCBs) allows higher LED densities to be used in circuit board designs and allows mounted LEDs to be driven at higher currents while still remaining within temperature tolerances. Using an aluminum-based backing design allows the designer to reduce the safety margin for power LEDs and derate the LEDs compared to conventional PCB designs. As with all components, the cooler the operating temperature of the LEDs in the design, the longer those LEDs can be expected to operate before failing.

Other applications for aluminum-based PCB designs include high-current circuits, power supplies, motor controllers, and automotive applications. Aluminum-based PCBs are the ideal thermal solution for any design using high-power surface mount ICs. Additionally, they can eliminate the need for forced ventilation and heat dissipation, ultimately reducing design costs. Essentially, any design that can be improved with higher thermal conductivity and better temperature control is a possible application for aluminum substrate PCBs.

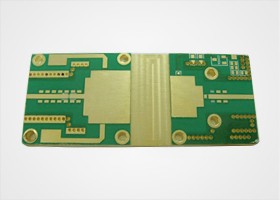

Where a conventional PCB uses a fiberglass substrate (FR4 is the standard substrate used by PCB manufacturers), an aluminum substrate PCB consists of an aluminum substrate, a high thermal conductivity dielectric layer, and a standard circuit layer. The circuit layer is essentially a thin PCB that has been bonded together with an aluminum-based backing layer. In this way, the circuit layers can be as complex as those mounted on conventional fiberglass backings.

Although it is more common to see single-sided designs, aluminum-based designs can also be double-sided designs, with circuit layers connected to both sides of the aluminum base through a highly thermally conductive dielectric layer. These two side designs can then be connected via plated through holes. Regardless of the configuration, the aluminum base plate provides an excellent thermal path to the surrounding environment or any connected heat sinks. Again, improving the thermal conduction of power components is the best way to ensure design reliability, and aluminum PCBs provide an excellent solution to this problem.

As with traditional PCB design, the solder mask on the circuit portion of the board can be made in many different colors. That said, in LED designs, the solder mask is usually white. The white solder mask allows the associated LED array to produce higher levels of light reflection and result in a more efficient design. In power supply designs, the solder mask is also usually painted black to dissipate heat better.

Aluminum-based PCB designs are also highly mechanically stable and can be used in applications that require a high level of mechanical stability or are subject to significant mechanical stress. Also, they are less affected by thermal expansion than glass fiber-based structures. If your design does not require a high level of thermal conduction, but the board will be subject to significant mechanical stress or has very tight dimensional tolerances and will be subject to significant heat, an aluminum baseboard design may warrant it.

Finally, aluminum is not a usable metal backing material. Copper and copper alloys are also used as backing materials, although less popular due to their generally higher cost. Copper and copper alloys offer higher performance than aluminum in terms of heat dissipation. Therefore, if a standard aluminum-based design cannot meet the thermal requirements of the design, copper can be considered as the next step in solving the problem.

All in all, using an aluminum-based solution can greatly improve the reliability and longevity of the design through temperature control and the resultant lower component failure rate. In addition to excellent temperature control properties, the aluminum design provides high levels of mechanical stability and low levels of thermal expansion. When a standard fiberglass (FR-4) backplane cannot meet the thermal and density requirements of your design, aluminum substrates may provide the answer.

Read recommendations:

Six-layer Immersion Gold Board (BGA)

Six-layer Immersion Gold Board (BGA)

Circuit board manufacturers: 5 points that cannot be ignored in PCB circuit boards in power supply d

Popular recommended products

Laminate copper-based PCB after 4L (sample)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27Display board (six layers)

2021-04-27Network communication board (sixth floor)

2021-04-29Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Single copper base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Single-sided double-layer AL base PCB

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27Computer card board (four layers)

2021-04-25Aluminum substrate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Mobile phone template (six layers)

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-27SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-04-27DIP plugin

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Related Information

The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13What is the difference between RO filter and PCB filter

2023-11-06Method for determining blind hole PCB board

2023-11-01Electronic Manufacturing Services PCB!What are the effects of PCB board color on performance?

2023-10-23Introduction to the Manufacturing Steps and Requirements of PCBA Test Stand

2023-10-16PCB version maturity stage.AOI circuit board price

2023-09-25How to maintain a PCB circuit board

2023-09-19Development Trend of Printed Circuit Board.Zener diode PCB Vendor

2023-09-14Common problems and cause analysis of PCB circuit board sampling.Zener diode PCB price

2023-09-08What are the issues that need to be understood in PCB circuit board design?IGBT module PCB factory

2023-09-08How to reduce the risk of bending and deformation in PCB circuit board production?Inverter PCB Produ

2023-08-16What are the three main factors that constitute welding defects in PCB circuit boards?Multilayer PCB

2023-08-16The structure of a glass teapot.LCD Module PCB factory

2023-08-11Glass teapot.Inverter PCB Processing

2023-08-11PCB online debugging

2023-08-08