source:Industry News release time:2022-06-22 Article author:yu Popular:pcb

Ink is an indispensable raw material for HDI circuit board/blind via board/buried via board, which mainly plays the role of protecting the circuit board, protecting the copper skin from oxidation, insulation and so on. Whether the quality of HDI circuit board/blind orifice/buried orifice ink is excellent is reflected in its own viscosity. The English is: viscosity, that is, the shear stress of the flow divided by the velocity gradient in the direction of the flow layer, and the unit is Pa/sec.

Plasticity: refers to the performance of the ink to maintain the previous shape after being subjected to external force, and the plasticity can improve the printing accuracy of the ink.

Thixotropy: The ink is gel-like when there is no external force, and turns into another shape after being stressed.

Drying: The slower the ink dries, the better, but the faster the ink is transferred to the substrate, the better.

Hiding power: For HDI circuit board/blind via board/buried via board ink, high hiding power is required according to special purposes and requirements.

Viscoelasticity: It refers to the ability of the ink to rebound quickly after being cut off after squeegee printing. The better the resilience of the ink, the better the printing.

Fluidity: fluidity is the flow of ink to the surrounding under the condition of external force, especially gravity. It is the reciprocal of viscosity. The greater the plasticity and thixotropy, the greater the fluidity.

Lass: When the ink is scooped up with an ink shovel, it will appear as a filament that does not break and become a wire drawing. The longer the wire drawing, there will be many filaments on the HDI circuit board, which cannot be printed.

The ink should be resistant to external scratches, thermal shock, mechanical peeling, etc. after use. And it must meet the international safety performance and environmental protection performance.

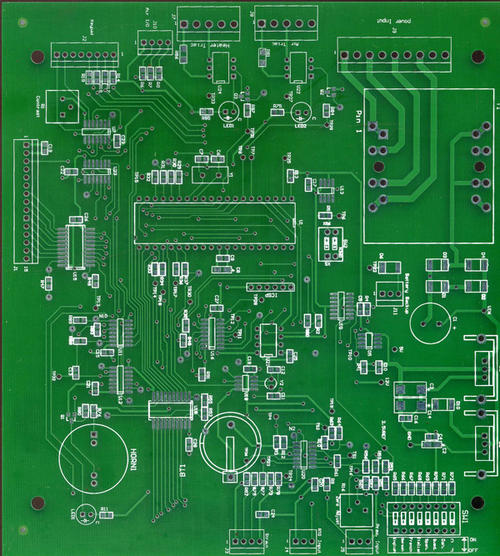

Commonly used ink colors for HDI circuit boards:

The most common ink color is generally green, and HDI circuit boards/blind via boards/buried via boards generally require photosensitive/matte green ink. Some other common colors are: black, white, yellow, red, blue, etc.

Read recommendations:

Mobile phone template (six layers)

Six-layer Immersion Gold Board (BGA)

Six-layer Immersion Gold Board (BGA)

Circuit board factory: what is the reason why the tin is not round in SMT chip processing.Automotive

Popular recommended products

High frequency PCB

2021-04-27Network communication board (sixth floor)

2021-04-29Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Mobile phone template (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Laminate copper-based PCB after 4L (sample)

2021-04-27Single-sided double-layer AL base PCB

2021-04-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27Computer card board (four layers)

2021-04-25Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Silver oil perforated plate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Single copper base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-27Aluminum substrate (double-sided)

2021-04-27Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Mobile phone board

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27DIP plugin

2021-05-27Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Related Information

The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13What is the difference between RO filter and PCB filter

2023-11-06Method for determining blind hole PCB board

2023-11-01Electronic Manufacturing Services PCB!What are the effects of PCB board color on performance?

2023-10-23Introduction to the Manufacturing Steps and Requirements of PCBA Test Stand

2023-10-16PCB version maturity stage.AOI circuit board price

2023-09-25How to maintain a PCB circuit board

2023-09-19Development Trend of Printed Circuit Board.Zener diode PCB Vendor

2023-09-14Common problems and cause analysis of PCB circuit board sampling.Zener diode PCB price

2023-09-08What are the issues that need to be understood in PCB circuit board design?IGBT module PCB factory

2023-09-08How to reduce the risk of bending and deformation in PCB circuit board production?Inverter PCB Produ

2023-08-16What are the three main factors that constitute welding defects in PCB circuit boards?Multilayer PCB

2023-08-16The structure of a glass teapot.LCD Module PCB factory

2023-08-11Glass teapot.Inverter PCB Processing

2023-08-11PCB online debugging

2023-08-08