source:Industry News release time:2021-10-18 Article author:sznbone Popular:pcb

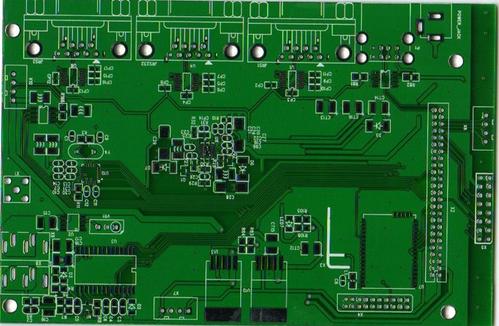

PCB circuit boards are widely used in electronics, computers, electrical appliances, mechanical equipment and other industries. It is the support of components and is mainly used to connect components to provide electrical. Among them, 4-layer and 6-layer circuit boards are common and widely used. Different levels of PCB layers can be selected according to industry applications. Below, let us understand the basic knowledge of PCB circuit board and the process of PCB board corrosion.

Printed circuit board:

Also known as printed circuit board, printed circuit board, printed circuit board for short, PCB (printed circuitboard or PWB (printedwiringboard) for short, using insulating board as the base material, cut to size, with at least one conductive pattern attached to it, and with holes (Such as component holes, fastening holes, metallized holes, etc.), used to replace the chassis of the electronic components of the previous device, and realize the interconnection between the electronic components. Because this board is made by electronic printing, so It is called a "printed" circuit board. It is not accurate to call a "printed circuit board" as a "printed circuit" because there are no "printed components" on the printed board but only wiring.

PCB circuit board is an important electronic component and a support for electronic components. The automatic soldering machine provides technical support for the soldering of PCB circuit boards, so that the development of electronic components can be improved. However, the problem of corrosion of PBC circuit boards has been plagued by automatic soldering vendors.

PCB circuit board corrosion process:

The corrosive liquid is usually made up of ferric chloride and water. Ferric chloride is a khaki solid, and it is easy to absorb moisture in the air, so it should be sealed and stored. When preparing the ferric chloride solution, 40% ferric chloride and 60% water are generally used. Of course, more ferric chloride is used, or warm water (not hot water to prevent the paint from falling off) can make the reaction faster Note that ferric chloride is extremely corrosive. Try not to touch your skin and clothes. Use cheap plastic basins for the reaction container, just fit the circuit board.

Start to corrode the PCB circuit board from the edge. When the unpainted copper foil is corroded, the circuit board should be taken out in time to prevent the paint from eroding away useful circuits. At this time, rinse with clean water, and scrape off the paint with bamboo chips by the way (at this time, the paint comes out of the liquid and is easier to remove). If it is not easy to scratch, just rinse it with hot water. Then wipe it dry and polish it clean with sandpaper, revealing the shiny copper foil, and a printed circuit board is ready. In order to preserve the results, the polished PCB circuit boards are usually coated with a rosin solution, which can not only assist the soldering, but also prevent oxidation.

Read recommendations:

Computer card board (four layers)

Popular recommended products

Six-layer Immersion Gold Board (BGA)

2021-04-27Mobile phone template (six layers)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27Computer card board (four layers)

2021-04-25Six-layer Immersion Gold Board (BGA)

2021-04-27Network communication board (sixth floor)

2021-04-29Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Aluminum substrate (double-sided)

2021-04-27Single copper base PCB

2021-04-27High frequency PCB

2021-04-27Single-sided double-layer AL base PCB

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27DIP plugin

2021-05-27DIP plugin

2021-05-27Mobile phone board

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13

CopyRight © 2007-2025

粤ICP备2021061255号

Address:

1205, Floor 12, Building 3, Chuangyi Office Building, No. 110, Ziheng West Road, Jinsha Community, Kengzi Street, Pingshan District, Shenzhen, Guangdong, China

Tel:

+86-755-29662580

Email:

sales@victoriapcb.com

PCB

PCBA

Service

Process

Tel: +86-755-29662580

Tel: +86-755-29662580 Email: sales@victoriapcb.com

Email: sales@victoriapcb.com

current position:

current position: