source:Industry News release time:2023-02-13 Article author:yu Popular:pcb

PCB is composed of Copper Clad Laminates (CCL), semi -curing tablets (PP tablets), copper foil (COPPER FOIL), and welded layer (also known as Solder Mask). At the same time, in order to protect the copper foil that is exposed on the surface and ensure the welding effect, the PCB needs to be treated on the surface, and sometimes it is equipped with characters for identification.

1) Copper foil layer pressure plate

Copper foil layer (CCL), referred to as copper foil plate or copper -covered board for short, is the basic material for manufacturing and printed circuit boards. Composite materials formed.

It was not until 1960 that there were professional manufacturers to make single -sided PCB based on formaldehyde resin copper foil, and put them into markets such as an electrocomputer, recorder, and video recorder. Later The stable epoxy glass substrate has been applied to this day. Now more use is FR4, FR1, CEM3, ceramic board and iron flopon plate.

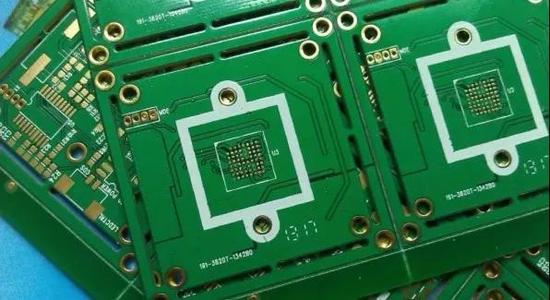

At present, the most widely used PCB made of etching method is selected on the copper -covered foil plate to etch to obtain the required line graphics. Copper foil boards mainly provide the function of conductivity, insulation and support on the entire printing circuit board. The performance, quality, and manufacturing cost of printing circuit board depends to a large extent on the copper foil board, as shown in Figure 8.

2) Semi -curing film

Semi -firing tablets, also known as PP tablets, are one of the main materials in multi -layer board production. They are mainly composed of resin and enhanced materials. The enhanced materials are divided into glass fiber cloth (referred to as glass cloth), paper base and composite materials.

Most of the semi -solidarial tablets (adhesive slices) used in multi -layer printed circuit boards are used as enhanced materials. The processed glass cloth is impregnated with the resin glue, and then the thin sliced material made of pre -baked is called semi -solidified tablets. Sympathetic tablets will soften under heating and cooler.

Due to the different yarn stocks of glass cloth in the meridian and werely direction unit, you need to pay attention to the latitude and weft direction of semi -solidified tablets when cutting. Generally, the meridian (the direction of the glass cloth curly) is the short -sided direction of the production board, and the weft direction is the weft direction is the weft direction is the weft direction is the weft direction. The long -sided direction of the production board to ensure the flatness of the board surface and prevent distortions after the production board is heated.

Read recommendations:

Six-layer Immersion Gold Board (BGA)

Popular recommended products

Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Mobile phone template (six layers)

2021-04-27Aluminum substrate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27Computer card board (four layers)

2021-04-25Six-layer Immersion Gold Board (BGA)

2021-05-24Single-sided double-layer AL base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Network communication board (sixth floor)

2021-04-29High frequency PCB

2021-04-27Single copper base PCB

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-27SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27DIP plugin

2021-05-27Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13