source:Industry News release time:2022-08-13 Article author:yu Popular:pcb

In the past few days, the pneumonia epidemic of new coronavirus infection has been surging, and masks have become the "standard" for epidemic prevention and control, and the "first line of defense" for personal protection. However, due to the sudden incident and the long Spring Festival holiday, the current demand for masks and other protective equipment for front-line medical staff is still difficult to meet, and the general public across the country has expressed that "one mask is difficult to find". Here, it is necessary to urgently appeal: qualified textile enterprises should immediately switch to expand production of civilian protective masks.

Due to the spread of the epidemic, the market demand for masks has exploded. On the one hand, in front-line hospitals, medical staff are directly exposed to the forefront of the ravages of the new coronavirus, and they need the protection of masks the most. Protecting medical staff is the key to fighting the new coronavirus. At the same time, masks are consumables and need to be replaced every four hours according to the epidemic protection tips. Recently, many hospitals across the country have issued fundraising announcements, announcing that masks and other protective equipment are in urgent need, and the medical field is already facing a huge gap; on the other hand, my country has a population of 1.4 billion, and there is a huge demand for masks from cities to remote rural areas. It is not only a tool to prevent the epidemic, but also an important item to calm people's hearts. In particular, the peak of the return journey of the Spring Festival travel is coming, and the sufficient supply of masks will directly affect the effectiveness of epidemic prevention and control.

Fortunately, my country is the world's largest producer and exporter of masks, accounting for about half of the world's annual output, with a maximum production capacity of more than 20 million masks per day. Since the outbreak of the epidemic, relevant ministries and related companies have gone all out to overcome all difficulties, and strive to promote mask manufacturers to work overtime to restore production capacity. At present, the output has reached more than 8 million per day, and the resumption of work and production has reached 40%. But 60% of capacity remains to be restored. Accelerating the recovery of production capacity remains a top priority.

But what should be seen is that even if the original mask production capacity is fully restored, compared with the huge demand of hundreds of millions, it is still only a drop in the bucket and cannot meet the urgent needs of the people. At the same time, we have a large number of textile enterprises that have the conditions and capabilities to produce masks, and can quickly switch to produce qualified virus protective masks for civilian use and stabilize people's hearts.

In the current special period of the "war epidemic" of the whole people, to promote more textile enterprises to switch to and expand the production of civilian protective masks, to provide a sufficient material basis for winning the epidemic prevention and control war, is not only an economic work that meets market demand, but also It is an urgent political task to stabilize people's hearts, and it requires all parties concerned to attach great importance to it, make joint efforts, and handle special cases. It is understood that the production of protective masks requires raw materials such as ordinary sanitary gauze, non-woven fabrics, and ultra-fine polypropylene fiber meltblown material layers. At present, upstream raw material manufacturers have fully resumed work, and the production capacity can fully support the production of more masks. For some difficulties and problems faced by qualified light textile enterprises in the process of converting production and expanding production, such as access qualifications, special equipment, raw material supply, employee return to work, personnel recruitment, etc., relevant departments should establish green channels, actively help docking, and speed up To solve the speed, put more resources and strength into the big event of mask production and supply.

It is worth noting that while the mask production capacity is gradually recovering and expanding, it is necessary to solve the "last mile" problem of mask distribution, and to do a good job in the control of the mask sales market. There have been some people rushing to hoard goods before, and some criminals have taken the opportunity to re-sell at high prices to make a profit. Expanding the supply of civilian protective masks cannot be a tool for some people to make profits. It is necessary to strengthen market supervision, investigate and punish illegal pricing behaviors, and maintain market order. Strengthen demand ration management to prevent looting and stockpiling, so that more people have the opportunity to buy mask products.

Read recommendations:

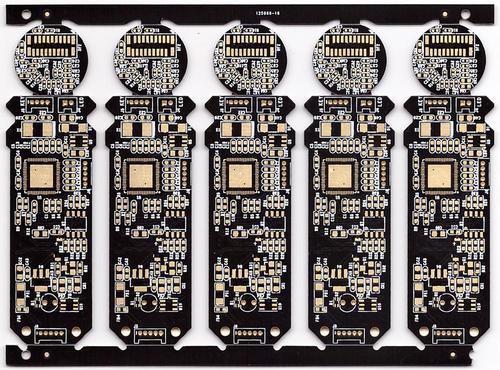

Computer card board (four layers)

Silver oil perforated plate (double-sided)

Popular recommended products

High frequency PCB

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27Mobile phone template (six layers)

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Single-sided double-layer AL base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Network communication board (sixth floor)

2021-04-29Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Aluminum substrate (double-sided)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Computer card board (four layers)

2021-04-25Single copper base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-04-27DIP plugin

2021-05-27Mobile phone board

2021-05-27DIP plugin

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13