source:Industry News release time:2022-05-11 Article author:yu Popular:pcb

The materials used by enterprises in the production of circuit boards contain many harmful substances, and many harmful substances are also produced in the production process, especially the "three wastes" generated, which will cause great harm to the environment. If left unchecked, it will not only harm the society The sustainable development of the economy has a serious impact and will also cause great harm to the human body. Therefore, for the printed board production industry, materials must be strictly controlled from the beginning of product design to the whole process of manufacturing and use, the production process must be improved, advanced non-polluting or low-polluting technologies must be used, and the electroplating of printed boards must be carried out. Strict monitoring and scientific management of the "three wastes" produced in the chemical production process, and strengthening of clean production management of printed boards are related to the survival of circuit board processing factories.

The concept and content of cleaner production in PCB board processing cleaner production includes cleaner production process and cleaner production products. In the concept of cleaner production, it includes not only technical feasibility, but also economic profitability. It should fully reflect the unity of economic, environmental and social benefits.

1. The concept of cleaner production Cleaner production refers to the continuous application of comprehensive preventive environmental strategies to production processes and products to reduce harm to humans and the living environment. For the production process, cleaner production includes saving raw materials and energy, eliminating toxic raw materials, and reducing the quantity and toxicity of all emissions and wastes before they leave the production process; for products, cleaner production strategies refer to reducing the amount of products in the whole process. The impact on the human environment during the life cycle, from the processing of raw materials to the final disposal of the product. Cleaner production is achieved by applying specialized technologies, improving processes and changing management. The purpose of cleaner production is to achieve rational utilization of resources and slow down the depletion of resources through comprehensive utilization of resources, substitution of scarce resources, utilization of secondary energy, and energy conservation, water conservation, and material conservation; in the production process, reduce or eliminate The generation and discharge of pollutants and wastes promote the compatibility of the printed board industrial production and product consumption process with the environment, and reduce the harm to humans and the living environment throughout the production cycle.

2. The goal of cleaner production in circuit board processing plants The goal of cleaner production is "energy saving, consumption reduction, comprehensive utilization, pollution reduction and efficiency improvement"; strengthen training, improve employees' ideological awareness and technical quality of cleaner production, strengthen production management, rely on technological progress, adopt Reasonable and practical process technology and other measures; in line with the principle of pollution control first and root cause, try not to use or use harmful substances as little as possible, so as to minimize and harmless the generation and discharge of pollutants in the production process, and waste in the production process. Be resourceful.

Read recommendations:

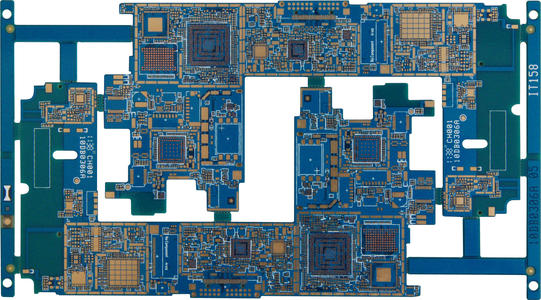

Computer card board (four layers)

Mobile phone template (six layers)

Six-layer Immersion Gold Board (BGA)

Teach you the circuit board manufacturer to write the 8D report required by the customer,Analyzer PC

Popular recommended products

High frequency PCB

2021-04-27Computer card board (four layers)

2021-04-25Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-27Network communication board (sixth floor)

2021-04-29Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-05-27Silver oil perforated plate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-04-27High frequency PCB

2021-04-27Mobile phone template (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Single-sided double-layer AL base PCB

2021-04-27High frequency PCB

2021-04-27Aluminum substrate (double-sided)

2021-04-27High frequency PCB

2021-04-27Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Single copper base PCB

2021-04-27SMT stickers

2021-05-27Mobile phone board

2021-05-27Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27DIP plugin

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13