source:Industry News release time:2022-04-08 Article author:sznbone Popular:pcb

Traditional circuit boards are often divided into single-sided PCB boards, double-sided circuit boards, and PCB multi-layer boards, and PCB multi-layer boards are further divided into single-press and multiple-press structures. This design of course involves some electrical properties and link density issues, but due to the rapid advancement of electronic product technology, these geometries cannot meet the component mounting density and electrical requirements. In order to increase the link density of components, from a geometrical point of view, only by compressing the space of lines and connection points, can more contacts be accommodated in a small space to increase the link density. Of course, multiple components can also be stacked in one position to increase the packing density. Therefore, high-density circuit boards are not only a circuit board technology, but also an issue of electronic packaging and assembly.

In order to improve the connection density of components, from a geometrical point of view, only by compressing the space between lines and connection points, so that more connections can be accommodated in a smaller space, the connection density can be improved. Of course, there is a different idea, that is, multiple different components can be stacked in the same location to increase the density of the construction. Therefore, from a certain point of view, high-density circuit boards are not only a technical problem of circuit boards, but also a problem of electronic assembly and assembly. This aspect is probably worth some effort by the industry to understand.

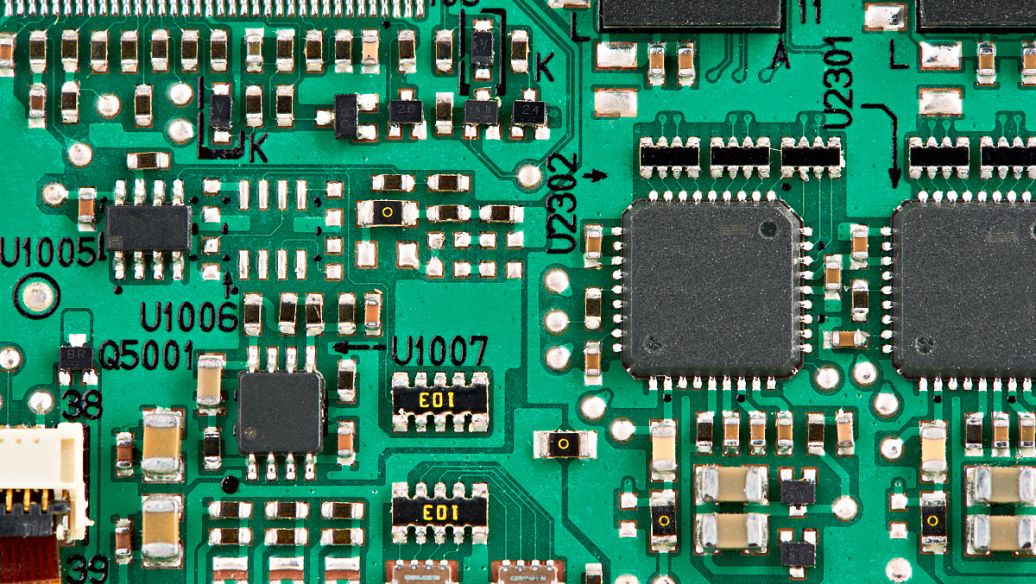

PCB multilayer board

Generally, the so-called electronic package refers to the connection between the semiconductor chip and the carrier board. In this regard, the Civil Road Board Association has published a special book on "electronic component carrier board technology", and those who are interested can refer to it. As for the electronic assembly part, it is the work of re-installing the components after the electronic assembly is completed on another functional circuit board. This connection, generally called OLB (outerleadbond), refers to the connection part of the outer pins of the component. The connection of this part is directly related to the surface contact density of electronic components. When the functions and integration of electronic products are getting higher and higher, and at the same time, the demand for mobility, thinness and multi-functionality is constantly pushed up. , of course there will be high densification pressure.

If a high-density circuit board design concept is adopted, electronic products can gain the following benefits:

1. The high-density circuit board structure adopts a thinner dielectric thickness, and the potential inductance is relatively low.

2. The micro-hole has a low aspect ratio, and the signal transmission reliability is higher than that of the general through-hole.

3. Micro holes can improve the flexibility of circuit configuration and make circuit design easier.

4. The same product design can reduce the number of carrier layers, increase the density and reduce the cost.

5. The use of micro-hole interconnection can shorten the contact distance, reduce signal reflection, and crosstalk between lines, and the components can have better electrical properties and signal accuracy.

6. Increase the wiring density and increase the line capacity per unit area with micro-hole thin lines, which can meet the assembly requirements of high-density contact components, and is conducive to the use of advanced assembly.

7. High-density circuit board micro-via technology allows the carrier board design to shorten the distance between grounding and signal layers, thereby improving RF/electromagnetic wave/electrostatic discharge (RFI/EMI/ESD) interference. The number of grounding wires can be increased to prevent the damage of components caused by instantaneous discharge due to static electricity accumulation.

Modern and popular electronic products should not only have the characteristics of mobility and power saving, but also have no burden to wear and look beautiful. Of course, the most important thing is that they are affordable and can be replaced with fashion.

Read recommendations:

Six-layer Immersion Gold Board (BGA)

Silver oil perforated plate (double-sided)

Six-layer Immersion Gold Board (BGA)

What is the impact of the Internet of Things on PCB manufacturing?

Popular recommended products

Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27Mobile phone template (six layers)

2021-04-27Computer card board (four layers)

2021-04-25Silver oil perforated plate (double-sided)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27Single copper base PCB

2021-04-27Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Network communication board (sixth floor)

2021-04-29Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-24High frequency PCB

2021-04-27Aluminum substrate (double-sided)

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-27Single-sided double-layer AL base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27SMT stickers

2021-05-27DIP plugin

2021-05-27Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13