source:Industry News release time:2022-09-14 Article author:yu Popular:pcb

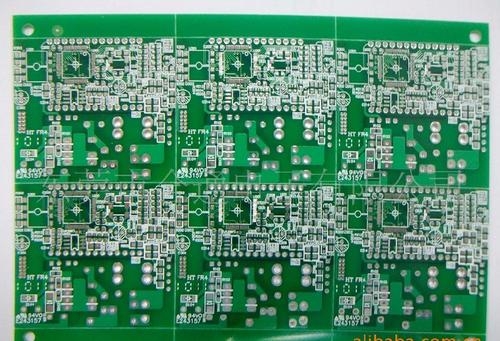

Copper cladding is an important part of PCB circuit board design. The so-called copper cladding is to use the idle space on the PCB as a reference plane and fill it with solid copper. These copper areas are also called copper pouring.

The significance of copper cladding is to reduce the impedance of the ground wire and improve the anti-interference ability; reduce the voltage drop and improve the power efficiency; connect with the ground wire to reduce the loop area. Also for the purpose of keeping the PCB from being deformed as much as possible during soldering, most PCB manufacturers also require PCB circuit board designers to fill copper or grid-like ground wires in the open area of the PCB circuit board.

We all know that in the case of high frequency, the distributed capacitance of the wiring on the printed circuit board will play a role. When the length is greater than 1/20 of the corresponding wavelength of the noise frequency, an antenna effect will occur, and the noise will be emitted through the wiring. . If there is a poorly grounded copper pour in the PCB, the copper pour becomes a tool for spreading noise.

Therefore, in high-frequency circuits, don't think that the ground wire is grounded somewhere, this is the "ground wire". Be sure to punch vias in the wiring at a spacing of less than λ/20 to be "well grounded" to the ground plane of the multilayer board. If the copper cladding is handled properly, the copper cladding not only increases the current, but also plays a dual role of shielding interference.

There are generally two basic ways of copper cladding, that is, large-area copper cladding and grid copper. People often ask whether large-area copper cladding is better or grid copper cladding is better. This is not a good generalization!

Large-area copper cladding has the dual functions of increasing current and shielding, but large-area copper cladding may cause the board to warp or even blister if it is subjected to wave soldering. Therefore, when a large area is covered with copper, several slots are generally opened to alleviate the blistering of the copper foil. WeChat public account: Shenzhen LED Chamber of Commerce

Simple grid copper cladding is mainly for shielding, and the effect of increasing the current is reduced. From the perspective of heat dissipation, the grid is good (it reduces the heating surface of copper) and plays a certain role in electromagnetic shielding.

Read recommendations:

Six-layer Immersion Gold Board (BGA)

Popular recommended products

Computer card board (four layers)

2021-04-25High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27High frequency PCB

2021-04-27Mobile phone template (six layers)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Silver oil perforated plate (double-sided)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Network communication board (sixth floor)

2021-04-29Single-sided double-layer AL base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-24Single copper base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27High frequency PCB

2021-04-27High frequency PCB

2021-04-27Aluminum substrate (double-sided)

2021-04-27Mobile phone board

2021-05-27SMT stickers

2021-05-27DIP plugin

2021-05-27DIP plugin

2021-05-27SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13