source:Optimization dedicated release time:2022-04-15 Article author:yu Popular:pcb

< on November 25, 2019

Classification

Industry news

With the development of the market economy and the growth of all aspects of life, you may not know much about PCBA processing. Today, I will talk to you about the topic of PCBA processing. Do you know the desoldering methods for PCBA processing? What are the common problems? Let's learn more about it with the editor of the board factory.

1. The basic principles of PCBA processing and desoldering:

Before desoldering, be sure to figure out the characteristics of the original solder joints, and don't do it lightly.

(1) Do not damage the pads and printed wires on the pcb circuit board (multilayer circuit board) during desoldering;

(2) Do not damage the electronic components, wires and surrounding components to be removed;

(3) For electronic components that have been judged to be damaged, the pins can be cut first and then removed, which can reduce damage;

(4) Try to avoid moving the position of other original devices. If necessary, you must do the restoration work.

2. Main points of PCBA processing and desoldering:

(1) Strictly control the heating temperature and time to avoid high temperature damage to other components. Generally, the time and temperature for desoldering are longer than those for soldering.

(2) Do not use excessive force when desoldering. The packaging strength of components under high temperature decreases, and excessive pulling, pressing and twisting will damage components and pads.

(3) Absorb the solder on the desoldering point. You can use a tinning tool to absorb the solder and unplug the components directly, reducing the desoldering time and the possibility of damaging the pcb circuit board (multilayer circuit board).

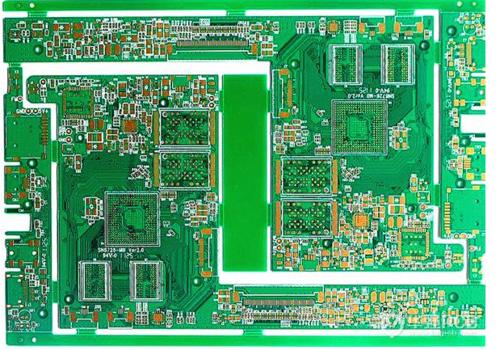

PCBA patch processing

PCBA patch processing

3. Desoldering method:

(1) Centralized desoldering method

Since the pins of the resistor row are soldered separately, it is difficult to heat them at the same time with an electric soldering iron. You can use a hot air soldering machine to quickly heat several solder joints, and pull them out at one time after the solder is melted.

(2) Point desoldering method

For horizontally installed RC components, the distance between the two solder joints is relatively far, and an electric soldering iron can be used to heat them in points and pull them out point by point. If the pins are bent, pry them straight with a soldering iron tip before removing them.

When desoldering, erect the pcb circuit board (multi-layer circuit board), while heating the pin solder joints of the components to be removed with an electric soldering iron, use tweezers or needle-nose pliers to clamp the component pins and gently pull them out.

(3) Shearing and desoldering method

If the component pins and wires on the desoldered point have excess, or determine that the components are damaged, you can first cut the components or wires, and then remove the wire ends on the pads.

(4) Retain the desoldering method

Use a de-soldering tool to absorb the solder from the soldered joints first. Components can usually be removed.

If you encounter multi-pin electronic components, you can use an electronic hot air blower for heating.

If it is a lap-soldered component or pin, you can dip the flux on the solder joint, use an electric soldering iron to solder the solder joint, and the component's pin or wire can be removed.

If it is a hook-welded component or pin, first use an electric soldering iron to remove the solder from the solder joint, and then heat it with an electric soldering iron to melt the residual solder under the hook, and at the same time, use a shovel to lift the pins in the direction of the hook line. Do not use too much force when prying to prevent splashing melted solder into your eyes or on your clothes.

4. Problems that should be paid attention to when re-soldering after PCBA chip processing and desoldering

(1) Pass through the blocked pad hole;

(2) The moved components are restored to their original state. ;

(3) Keep the re-soldered component pins and wires as original as possible.

Read recommendations:

Six-layer Immersion Gold Board (BGA)

Laminate copper-based PCB after 4L (sample)

Popular recommended products

Single copper base PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Mobile phone template (six layers)

2021-04-27Single-sided double-layer AL base PCB

2021-04-27Network communication board (sixth floor)

2021-04-29High frequency PCB

2021-04-27Aluminum substrate (double-sided)

2021-04-27High frequency PCB

2021-04-27Display board (six layers)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-27High frequency PCB

2021-04-27Computer card board (four layers)

2021-04-25Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-04-27Laminate copper-based PCB after 4L (sample)

2021-04-27Silver oil perforated plate (double-sided)

2021-04-27High frequency PCB

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-04-27Six-layer Immersion Gold Board (BGA)

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-05-24Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26Six-layer Immersion Gold Board (BGA)

2021-04-26DIP plugin

2021-05-27SMT stickers

2021-05-27Six-layer Immersion Gold Board (BGA)

2021-04-26Mobile phone board

2021-05-27SMT stickers

2021-05-27Mobile phone board

2021-04-27DIP plugin

2021-05-27Related Information

Composition of PCB

2024-09-29What is the difference between PCB and PCBA

2024-09-10PCB usage tips

2024-08-20Why do the circuit boards are green

2024-08-12How to clean the aluminum substrate?

2024-08-06Maintenance of Chemical Copper Plating Solution on PCB Board

2024-07-22single-sided PCB board and double-sided PCB board

2024-07-15PCB board production process flow

2024-07-09PCB CTI level

2024-07-01Via technology in circuit board factory.Automotive Electronics PCB

2024-06-25The role of FPC flexible circuit board solder mask

2024-06-18Detailed explanation of PCB board sampling production process

2024-06-11pcb v-cut depth standard

2024-05-27Multilayer Printed Circuit Board.What is the eq of PCB

2024-05-20The relationship between PCB safety distance and voltage

2024-04-22SMT surface mount processing.Hybrid circuit board PCB

2024-04-15PCB enterprises should pay attention to SMT matters.Electronic components PCB

2024-04-03PCB - the core building block of electronic products.Automotive Electronics PCB

2024-03-25PCB - the bridge and link of the electronic world

2024-03-18How to define high-frequency and high-precision circuit boards.Industrial Electronics PCB

2024-03-11USB PCB interface layout and wiring requirements

2024-01-22Electrolytic capacitor PCB.Steps for using PCB pins

2024-01-15Automotive ElectronicWhat aspects should be considered when processing and manufacturing PCB boards?

2024-01-08Electrolytic capaciWhat is the difference between a gold-plated circuit board and a gold-plated one?

2023-12-25When grinding PCB boards, attention should be paid to.Oscillator (belonging to crystal) PCB

2023-12-18Industrial Electronics PCB!What precautions should be taken when copying and grinding PCB boards

2023-12-11Do you know who is more suitable for LED direct display, regarding the difference between PCB board

2023-12-05Aluminum electrolytic capacitor PCB.What are the standards for selecting PCB boards

2023-11-27Surface Mount Technology (SMT) Phase PCB

2023-11-20Oscillator (belonging to crystal) PCB.The main functions of PCB board

2023-11-13